Equipment

i-MEET Equipment

Total space: 1430 m²

Laboratory space: 1100 m²

including 90 m² in the Technology Hall of the Department

including 180 m² at “auf AEG” (EnCN)

including 120 m² at Uferstadt Fürth

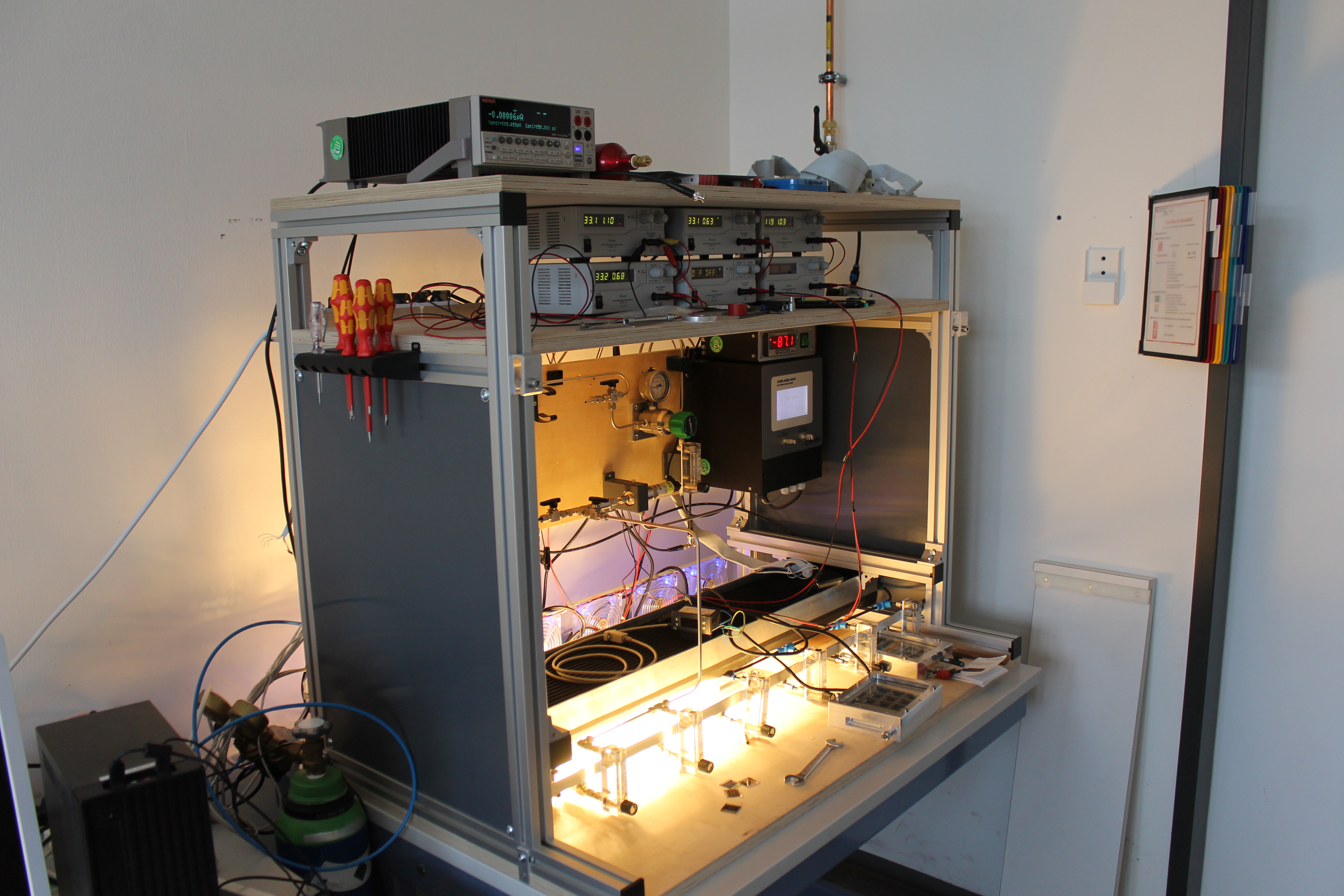

Parts of the equipment of our Institute include

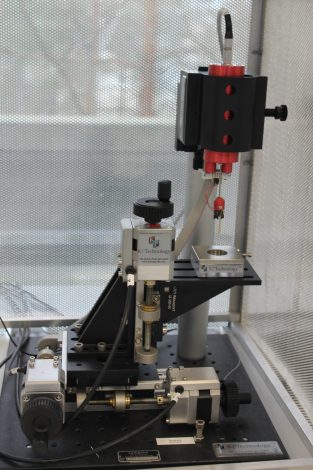

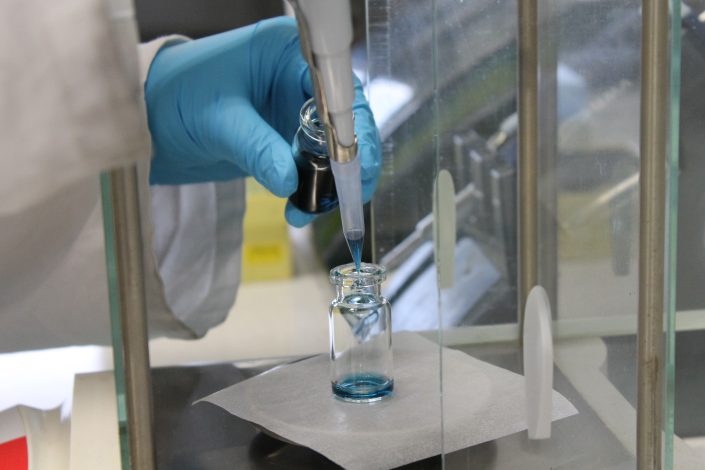

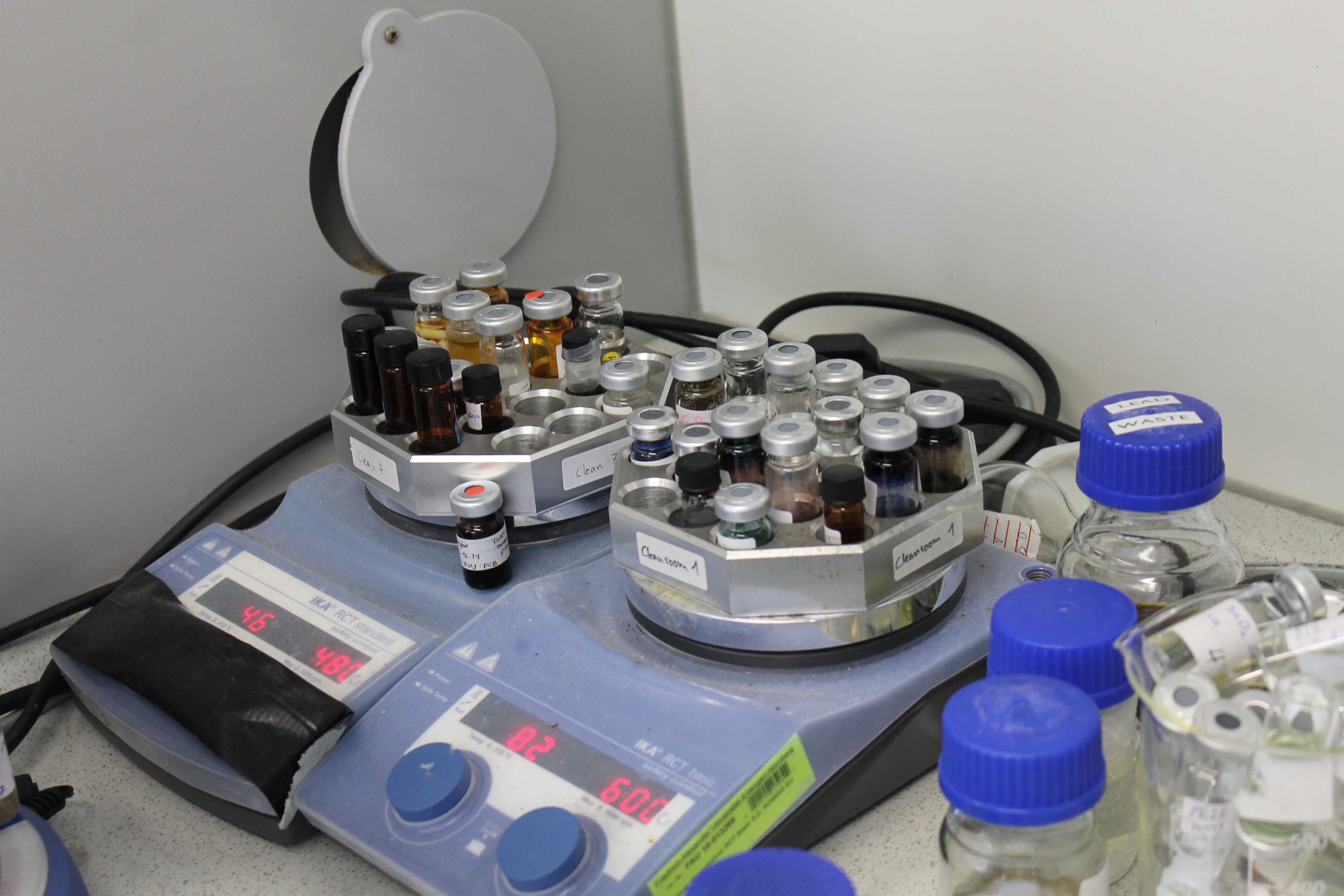

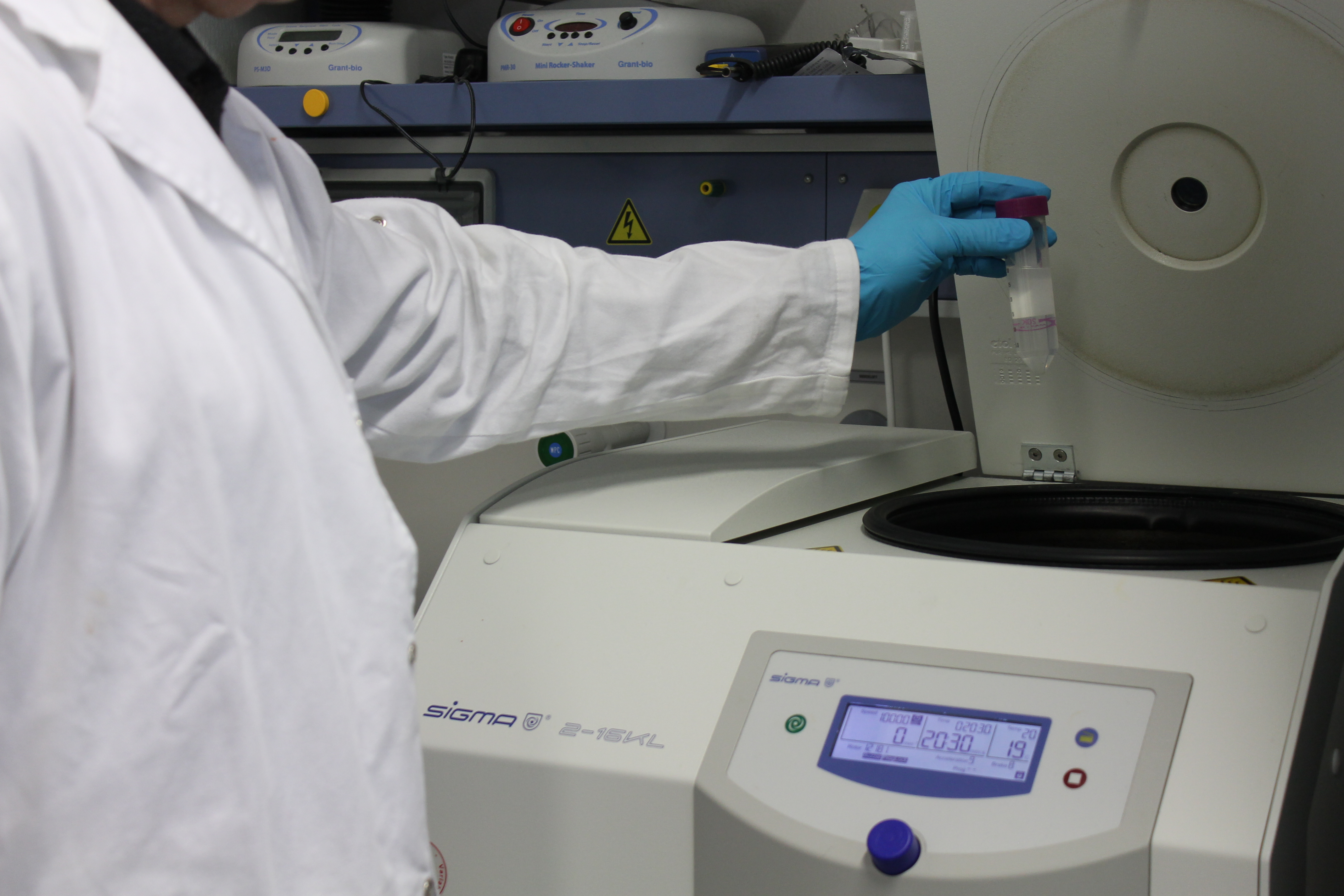

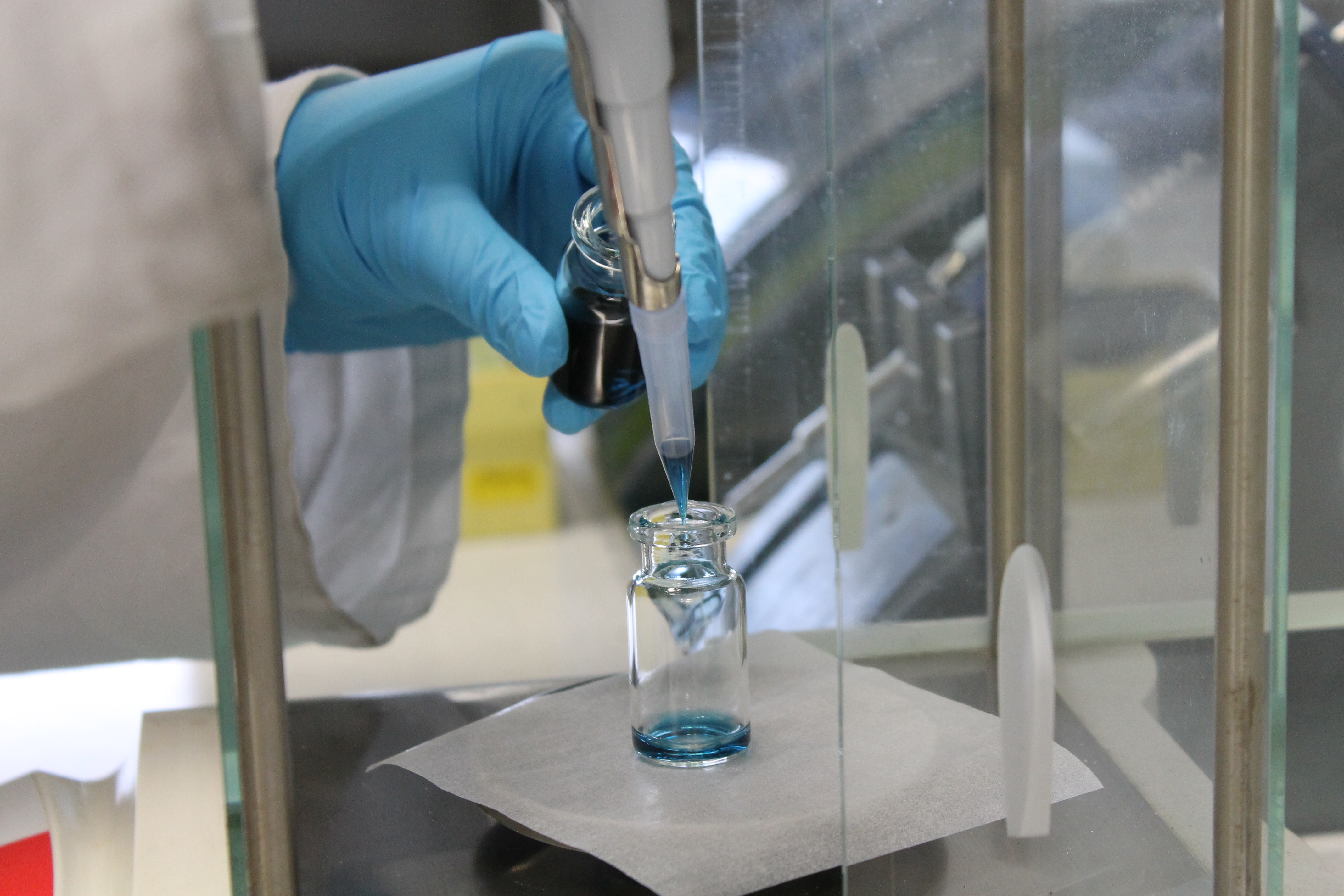

(Solution-based) sample preparation

- Aerosol Jet Platform

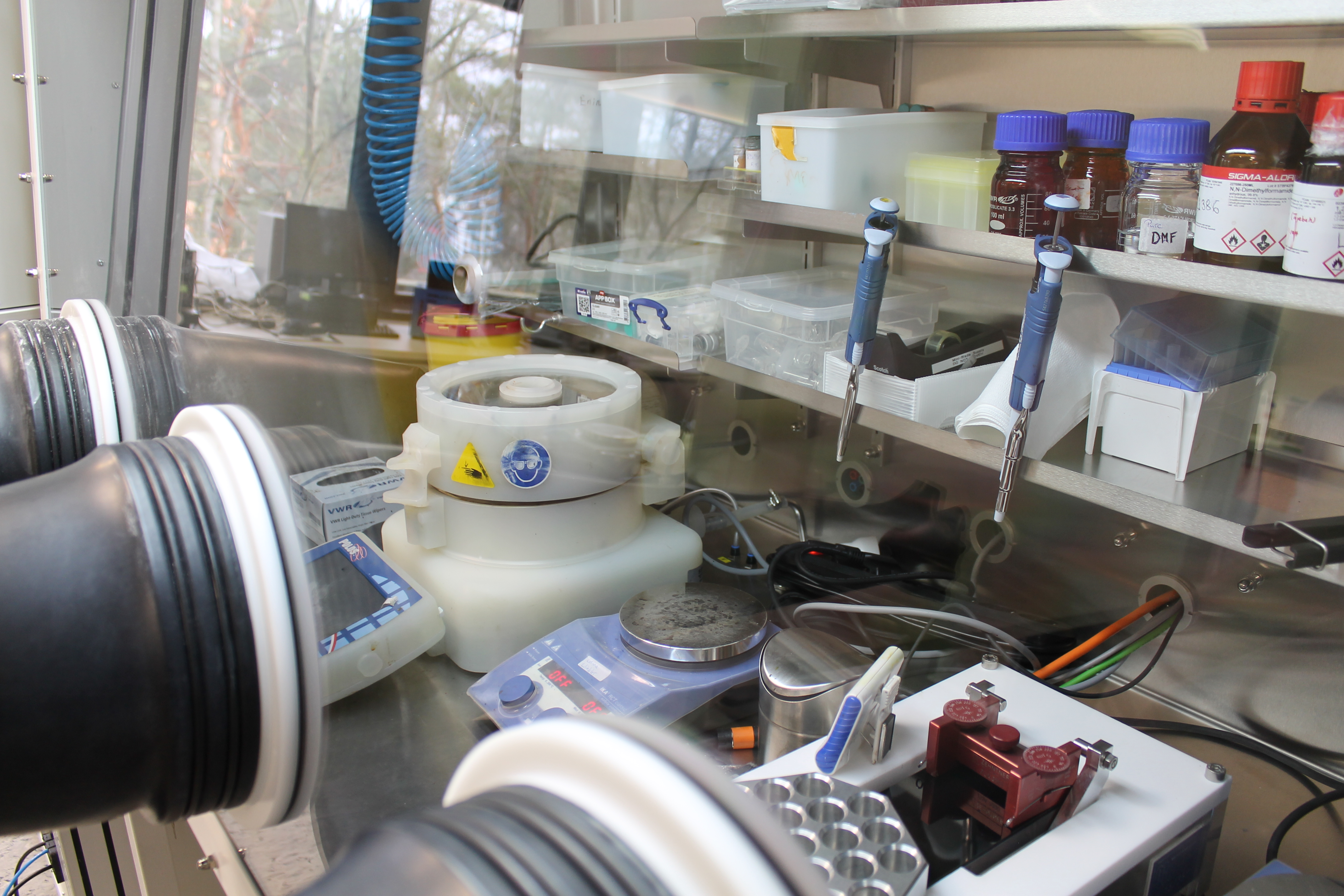

- Glovebox systems MBraun / Jacomex (GS Glovebox Systems)

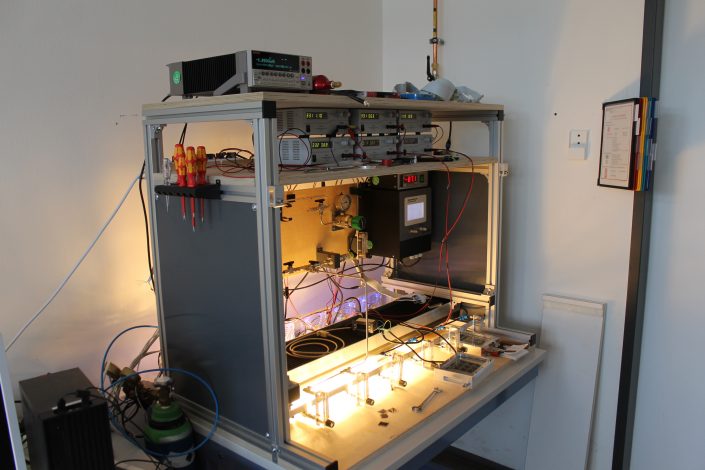

- Robotic setup for automatic synthesis and characterization of solvent-preocessed semiconductors

- Spraycoating Setup (Single Head)

- 15 powerful PCs for numerical modelling

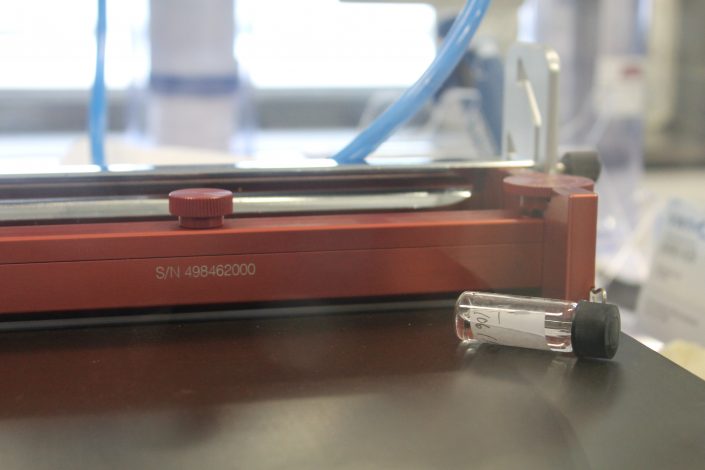

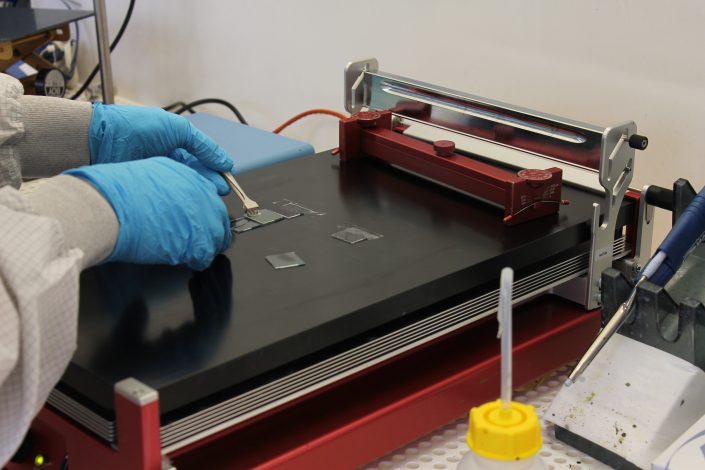

- Slot-die-Coater (FMP) (EnCN)

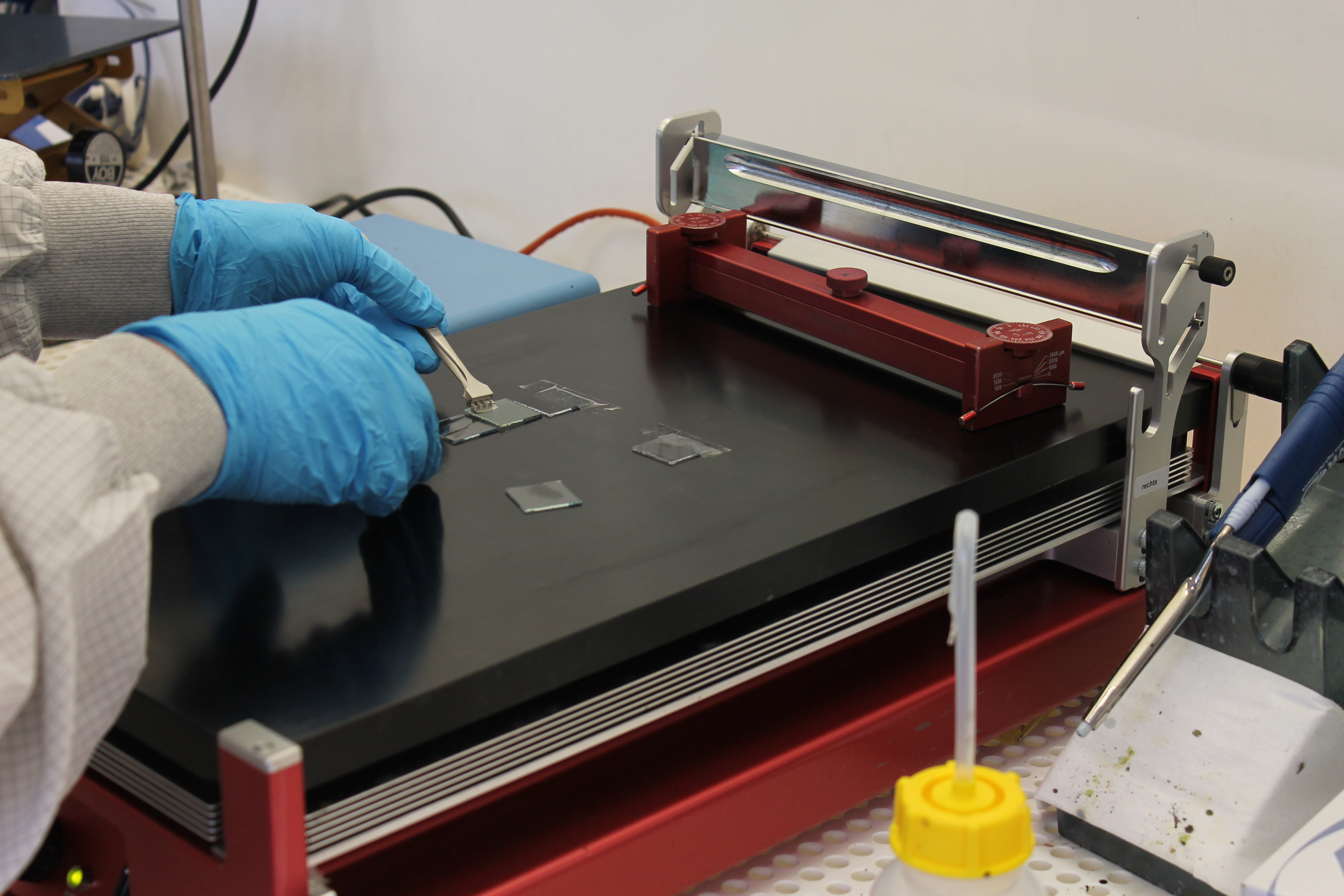

- 4 x ZAA 2300 Zehntner- Filmziehgerät Spezial

- Femtosecondlaser for materials processing , 1040 and 520 nm (HighQ Laser)

- Oerlikon 350G evaporator (Jacomex Glovebox)

- Evaporator (MBraun Glovebox)

- 3 x SPS Europe Spin150i Spincoater

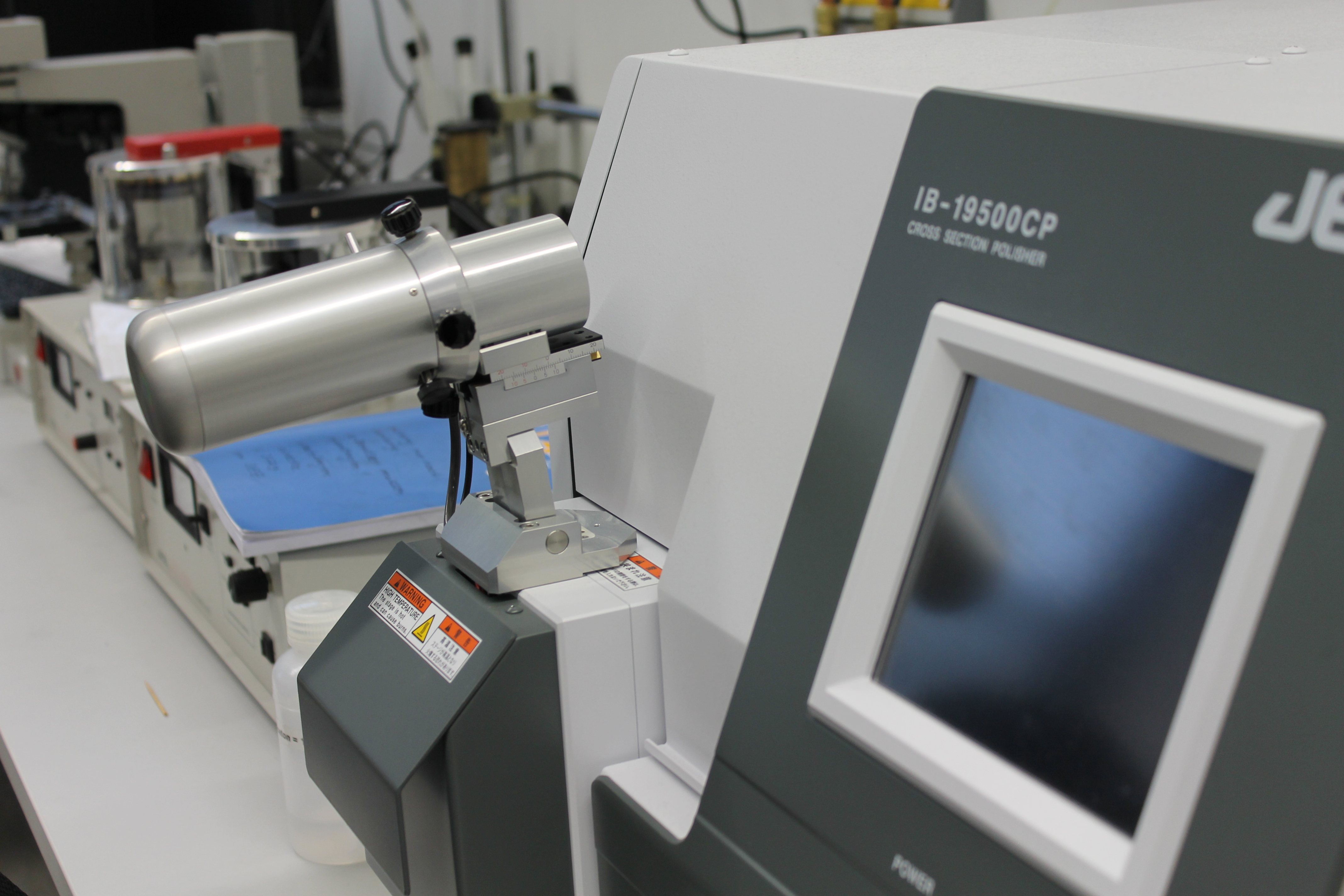

Materials Characterization

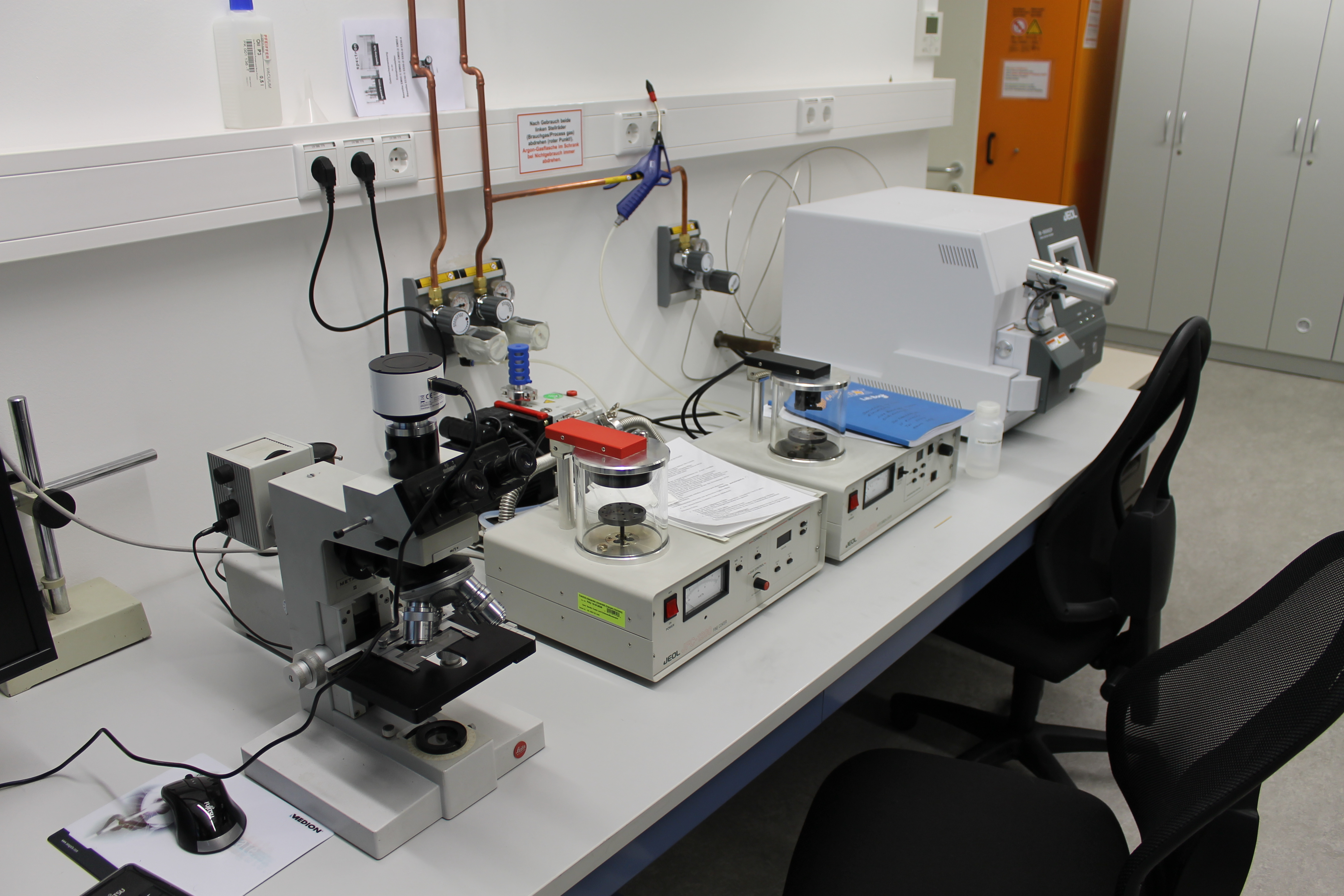

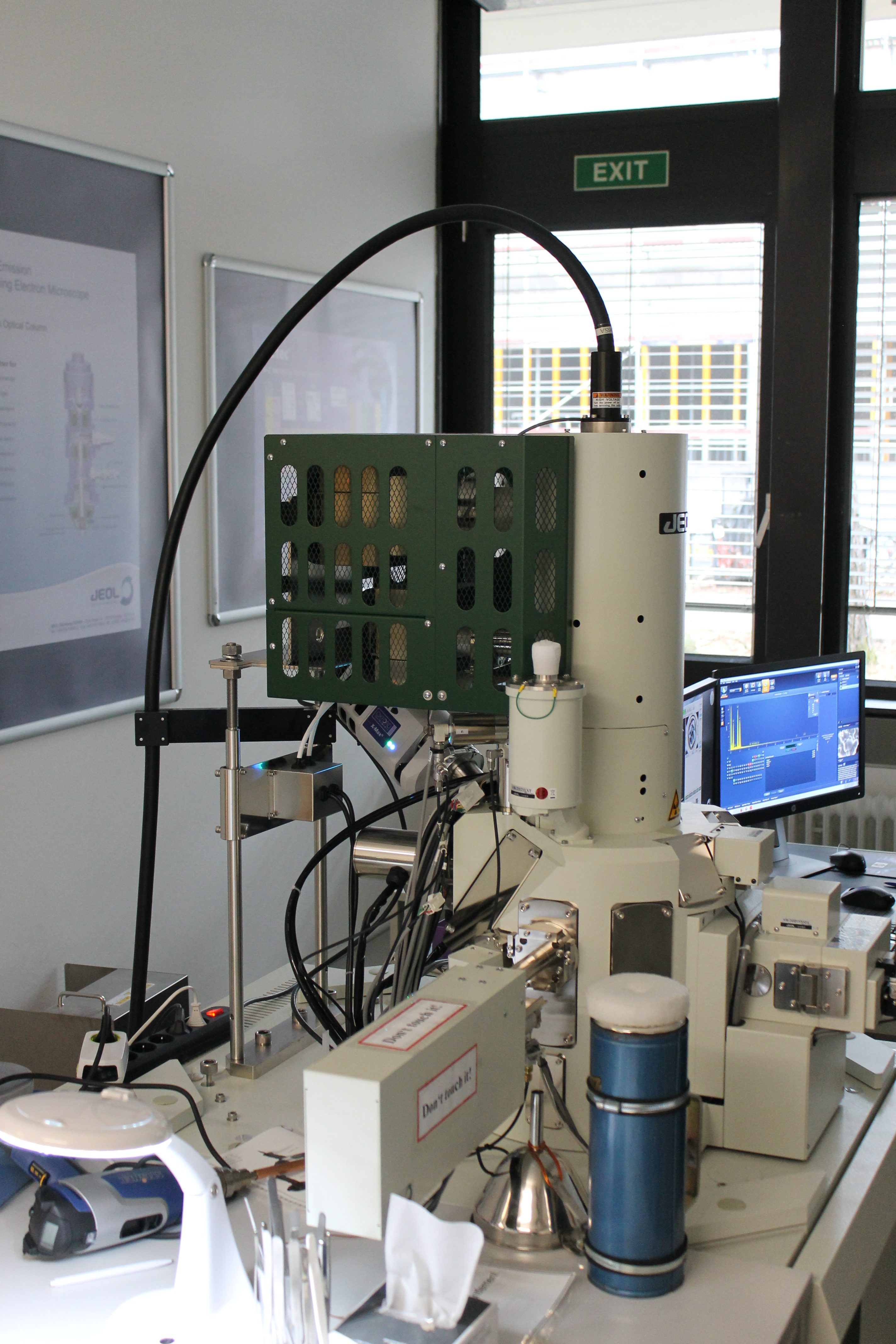

- Scanning electron microscope with CL and EDX (JEOL, JSM7610F)

- X-ray diffractometer (Panalytical)

- Particle size analyzer (Coulter LS100)

- Dynamic Light Scattering System (Nanoflex, Microtrack)

- UV-Vis absorption spectrometer, 190 – 3000 nm (Perkin Elmer Lambda 950)

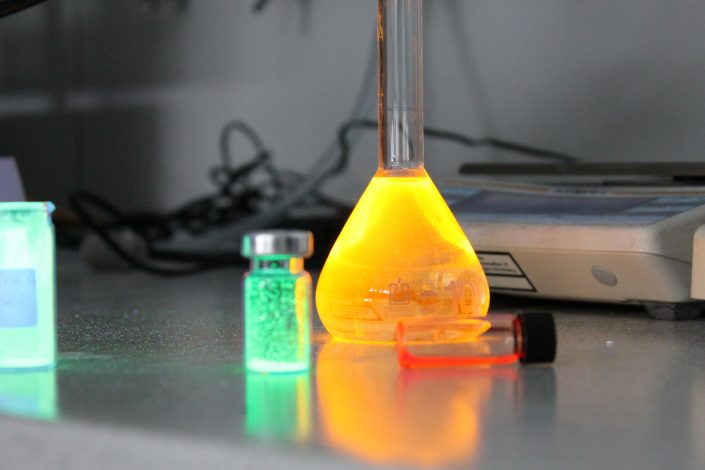

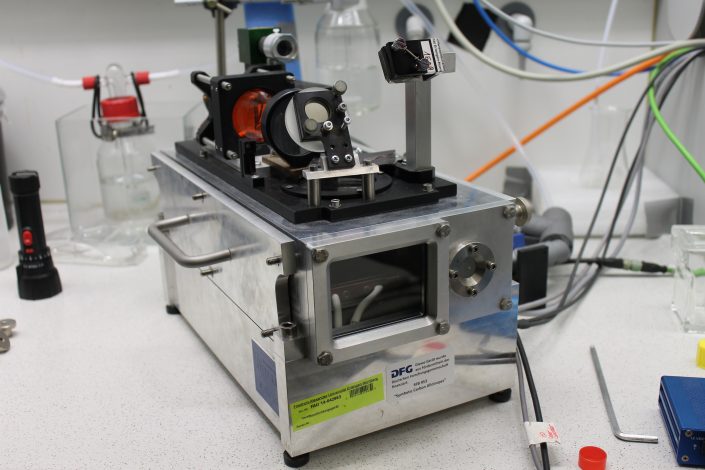

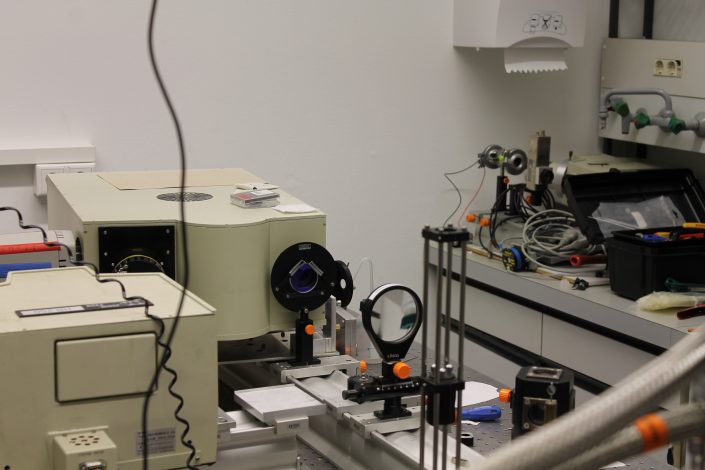

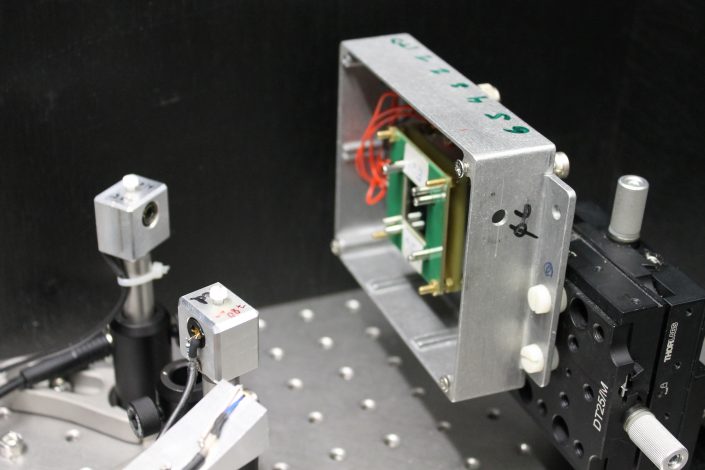

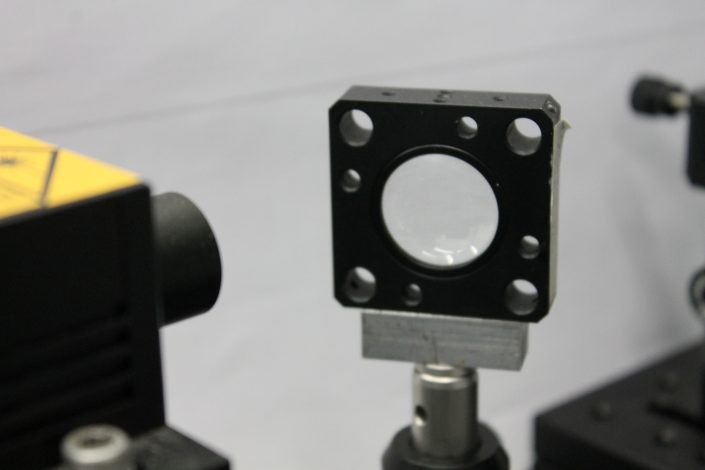

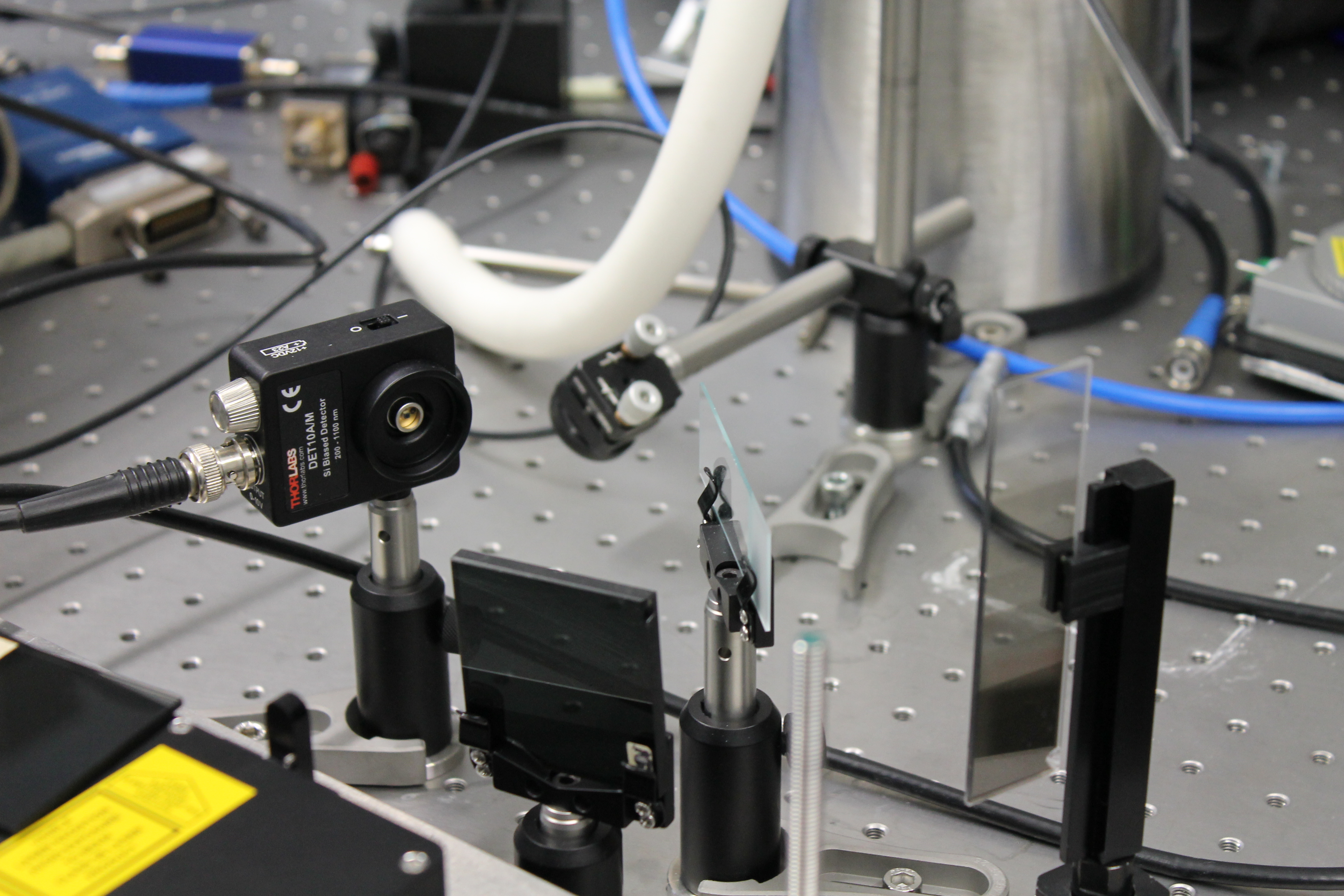

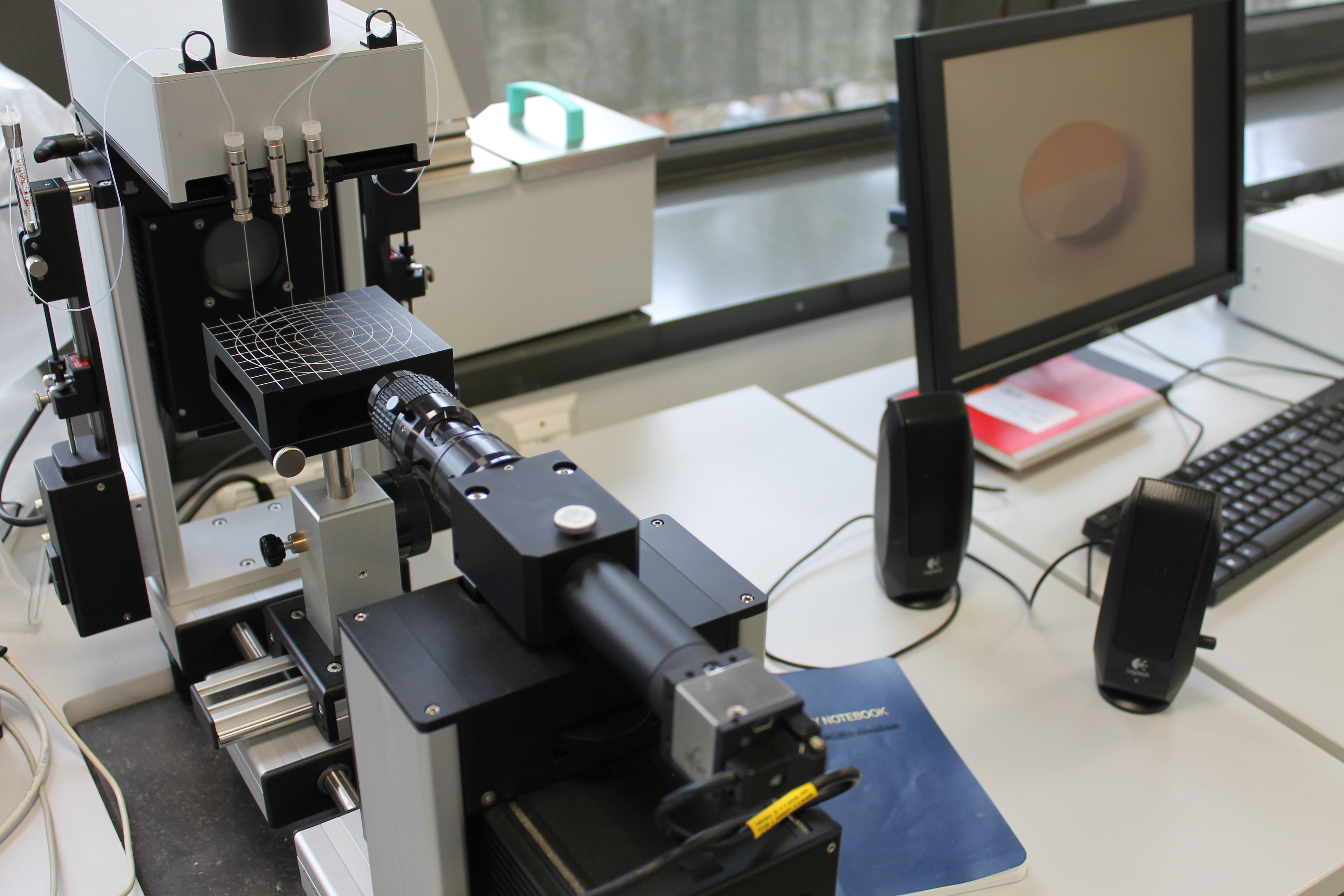

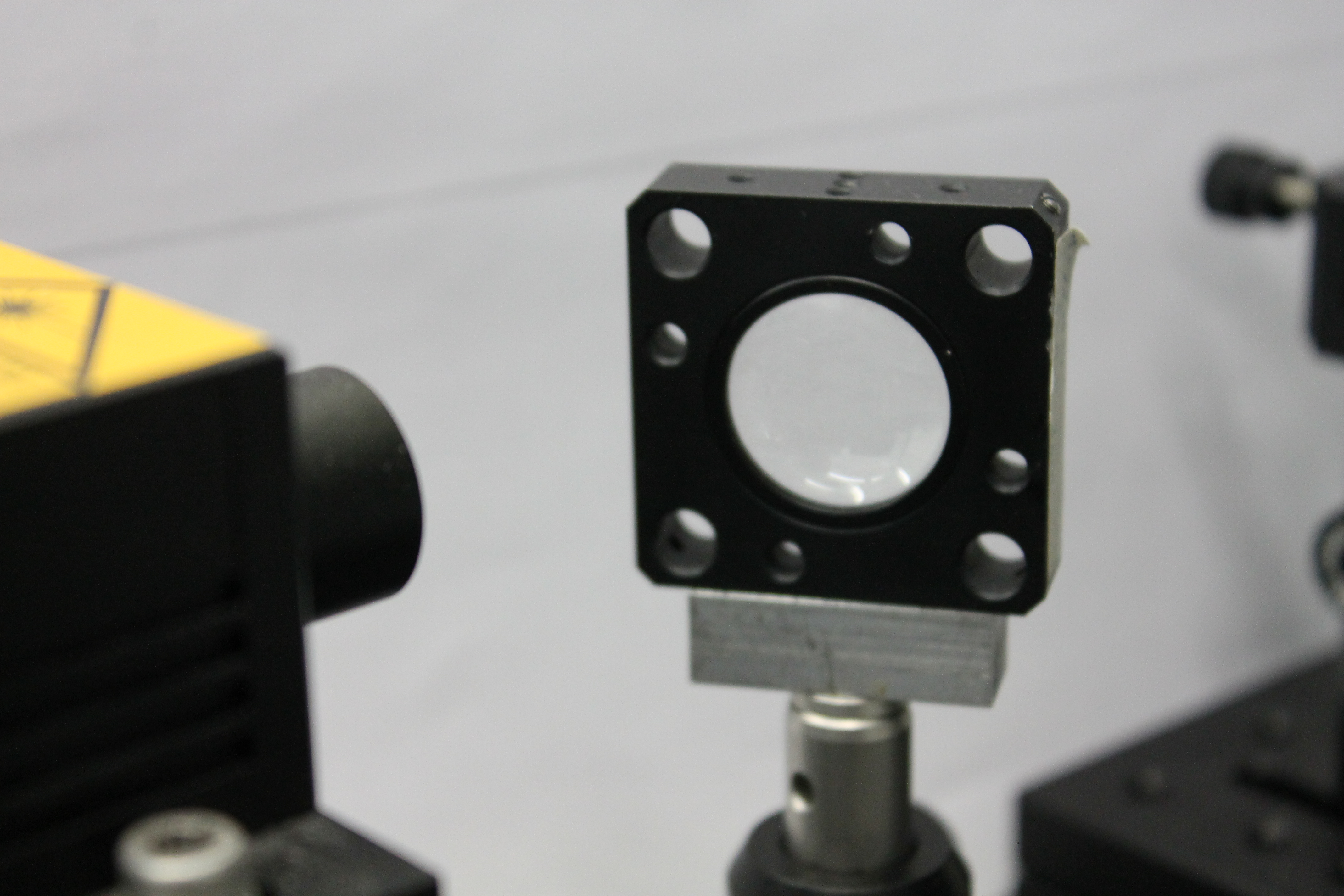

- Photoluminescence setup, detection 300 – 1600 nm, excitation wavelengths 325, 375, 488, 514, 632, and 975 nm

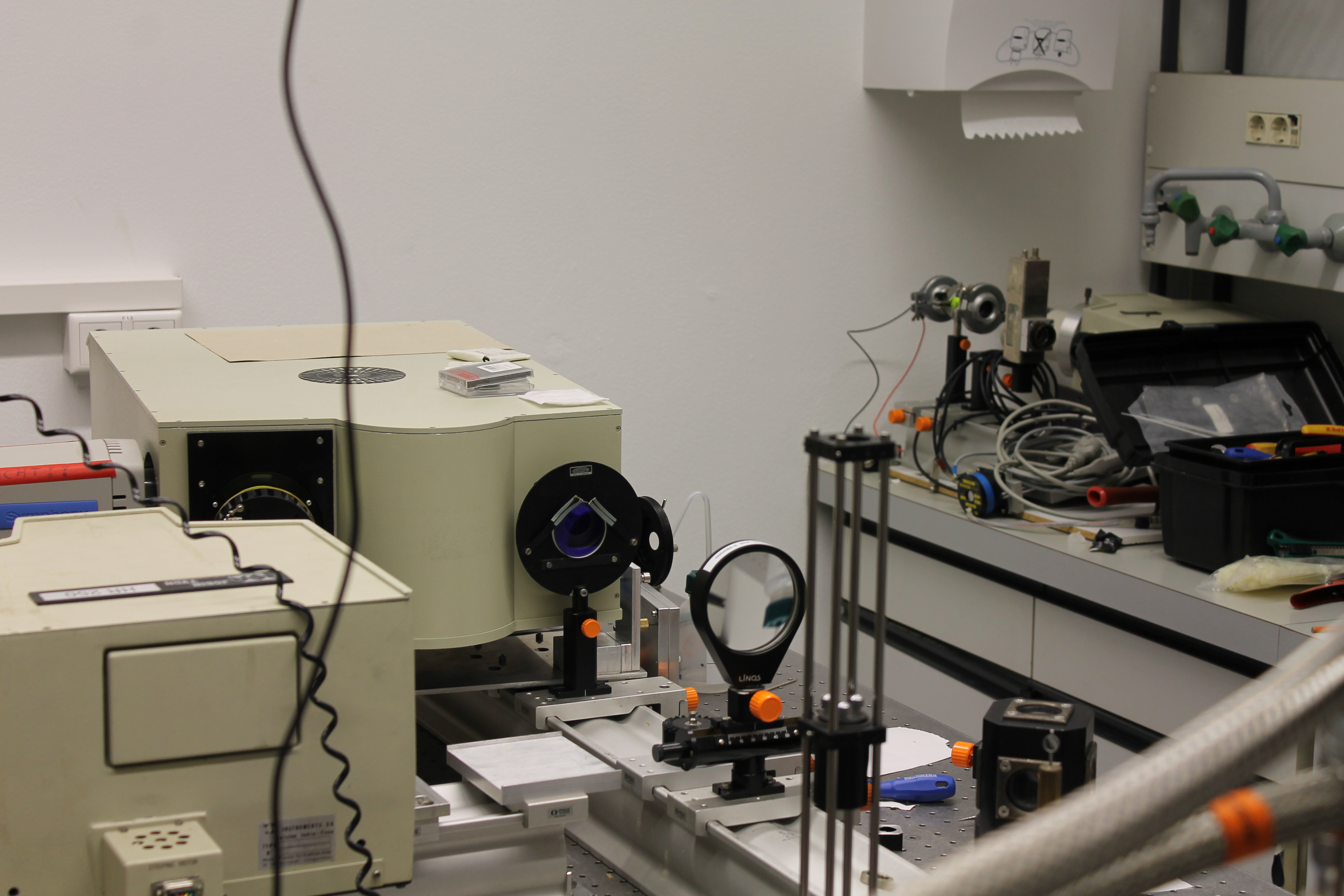

- Photoinduced Absorption Setup (pump 532 and 785 nm, Probe 500 – 1700 nm)

- Flourometer FP-8500 (Jasco, excitation 200 – 600 nm, detection 300 – 850 nm)

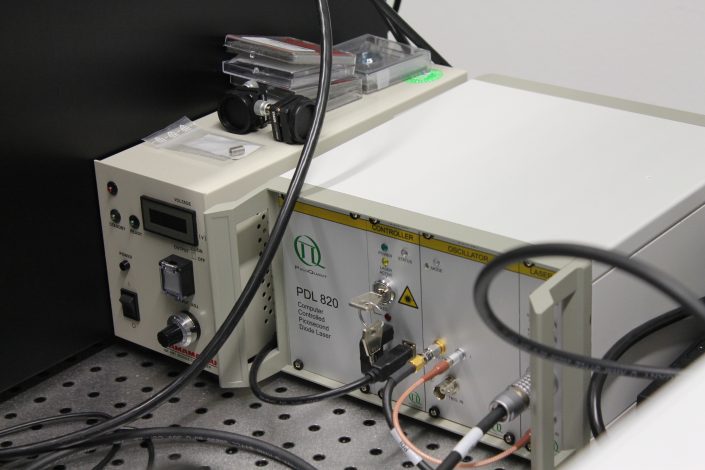

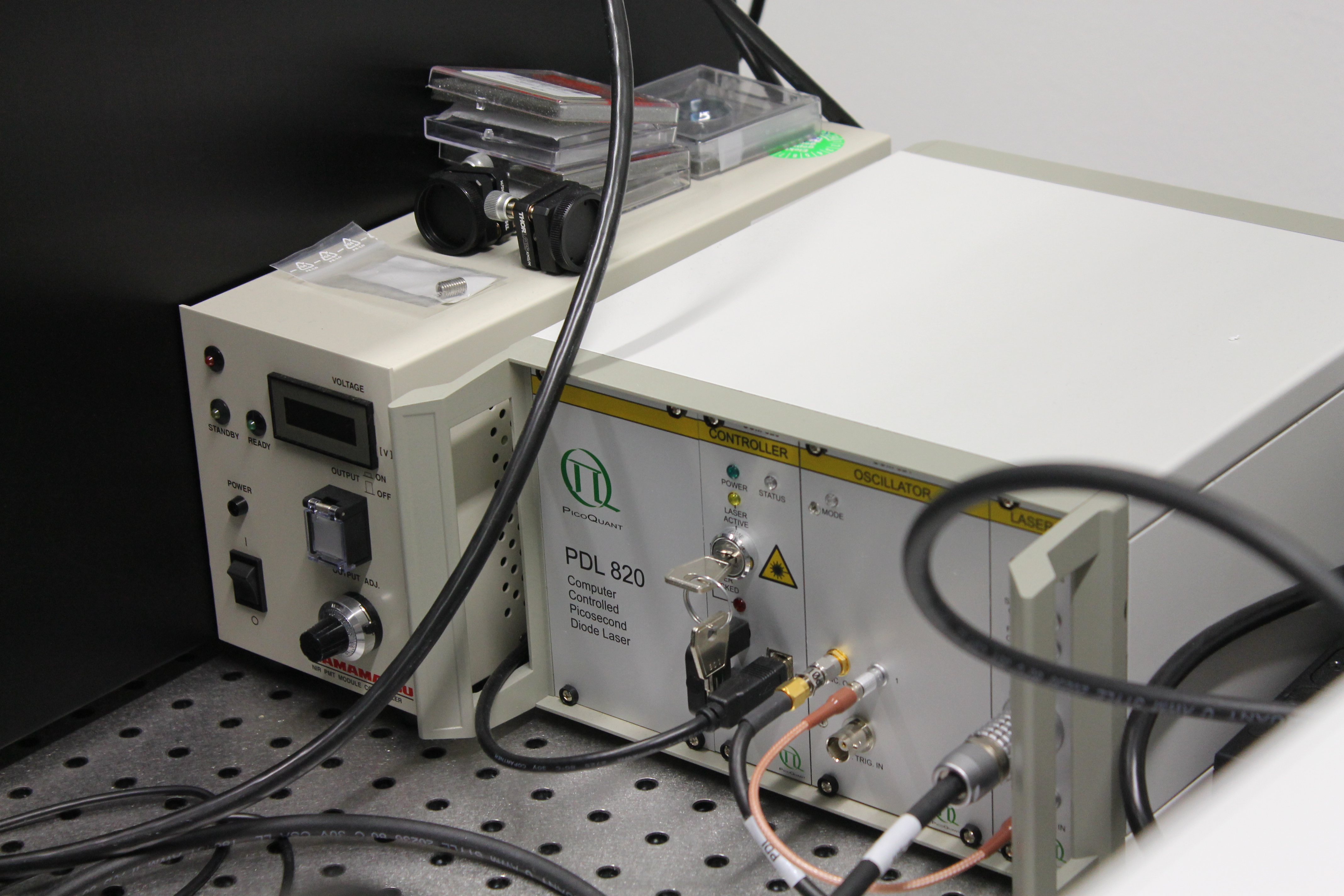

- Timeresolved fluorometer (PicoQuant FL300)

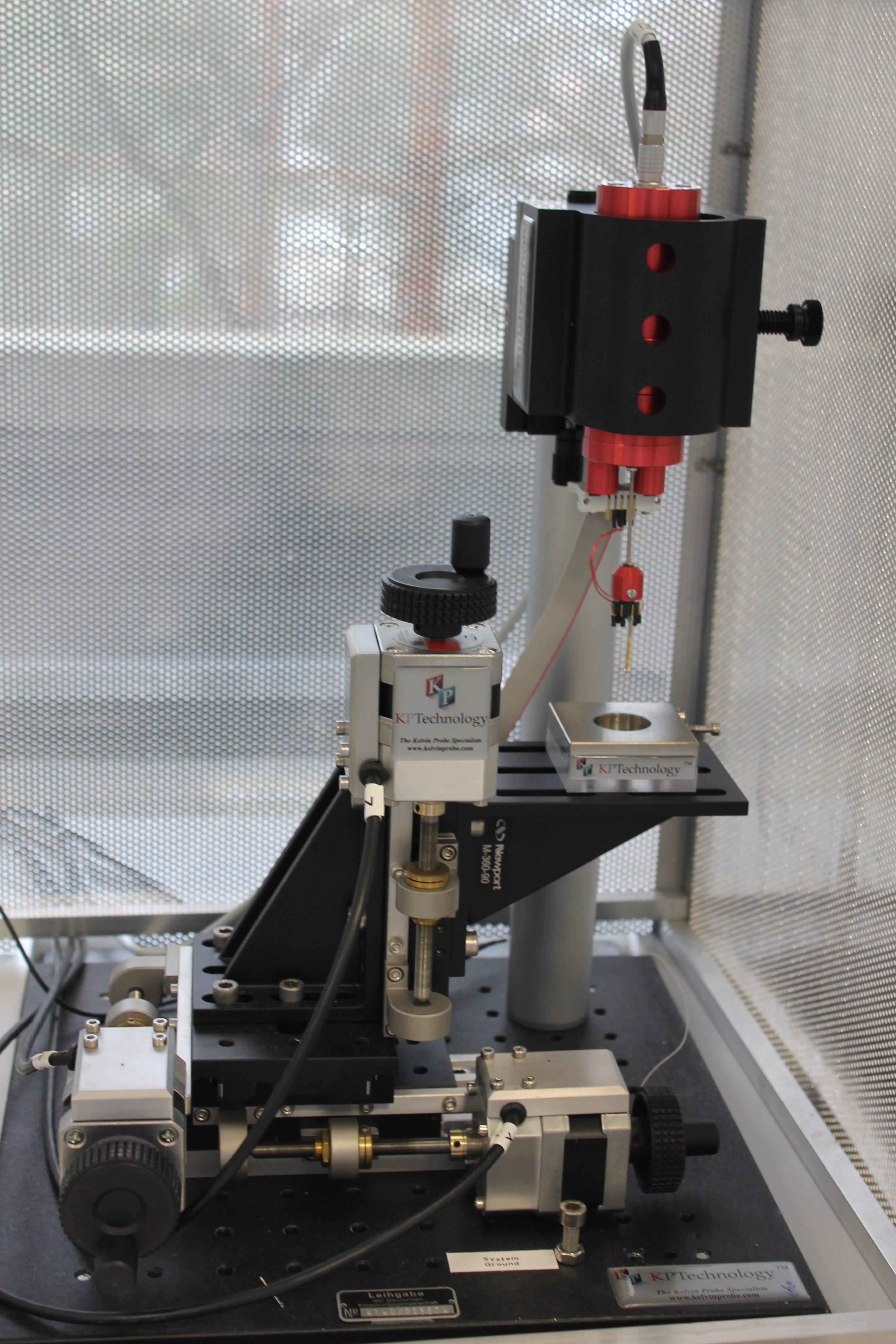

- Kelvin-Probe with surface Photovoltage Spectroscopy option

- Contact angle measurement OCA 20

- AFM Mikcroscope ( NT-MDT )

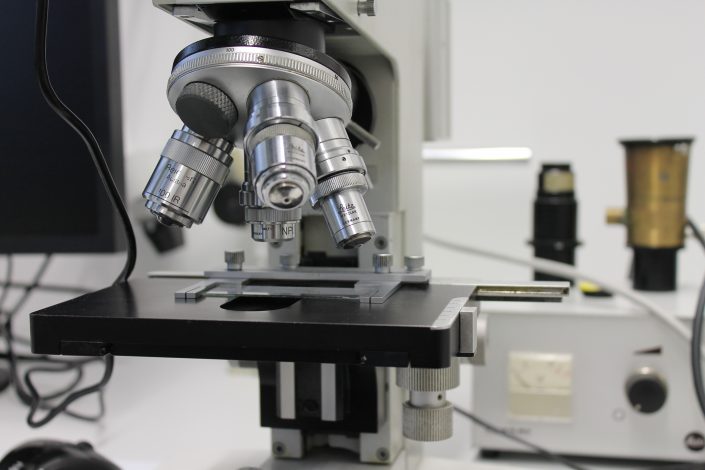

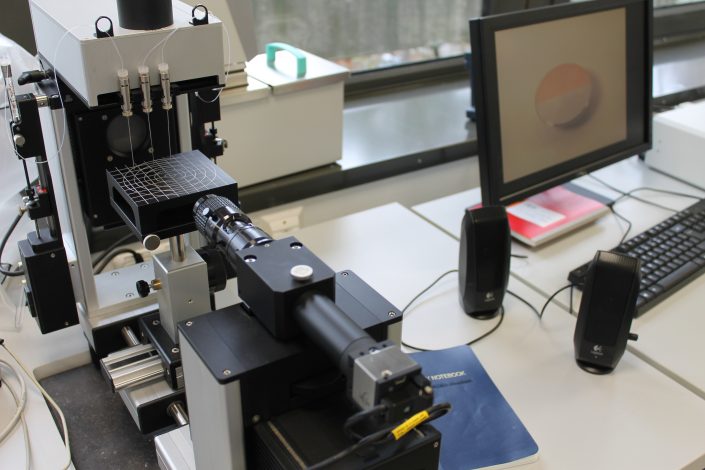

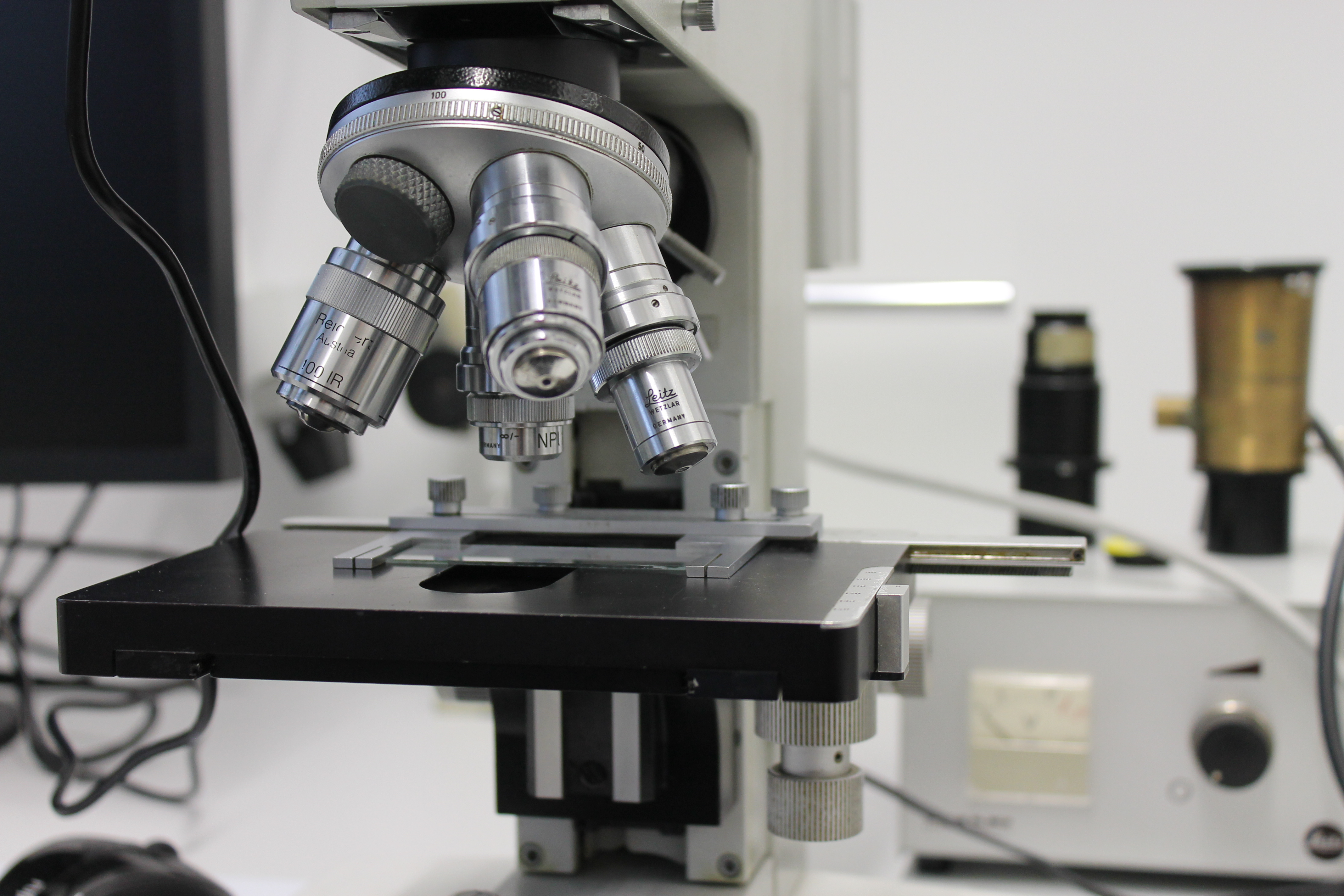

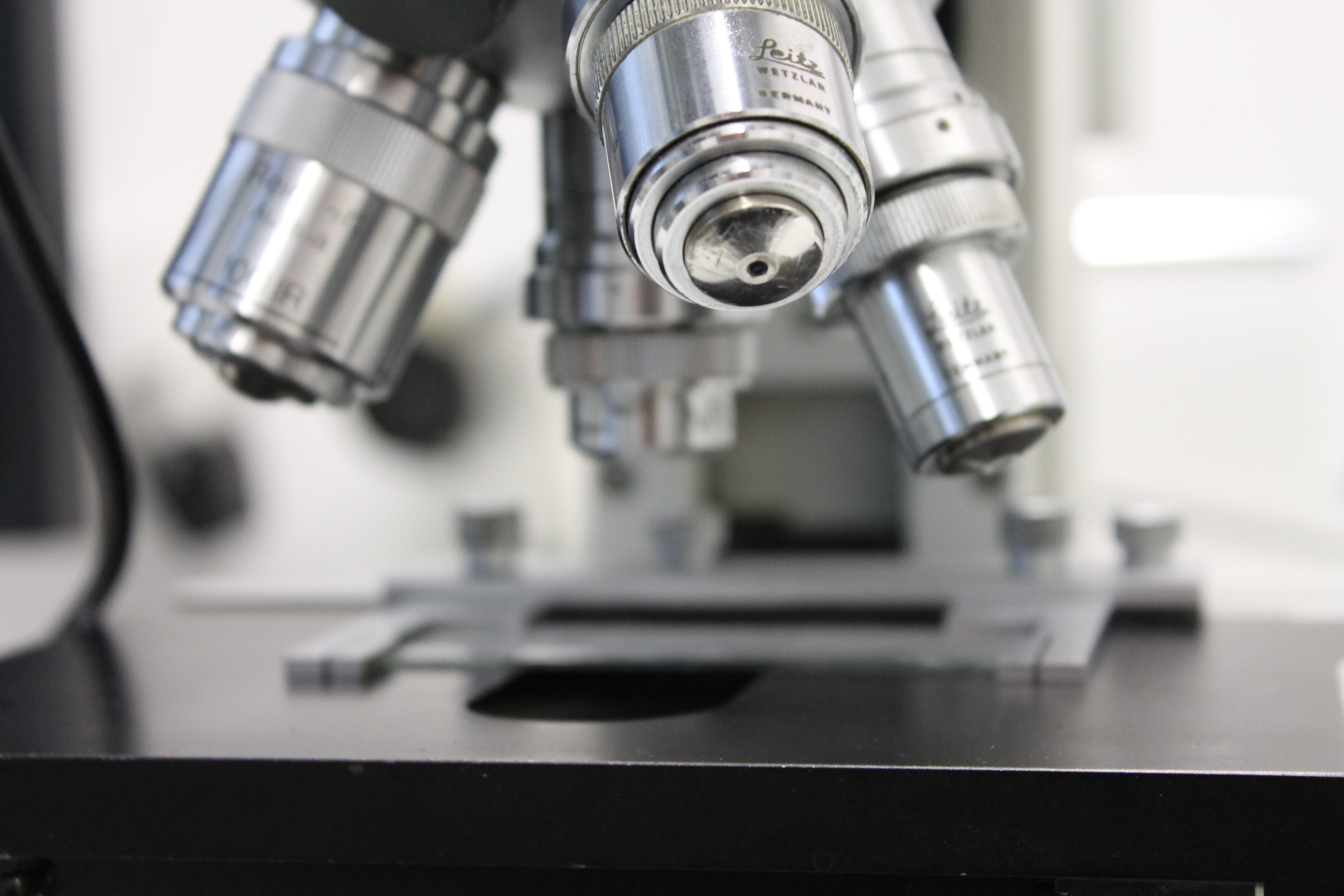

- Optical Microscope (Keyence)

- Rheometer HAAKE RheoStress 600

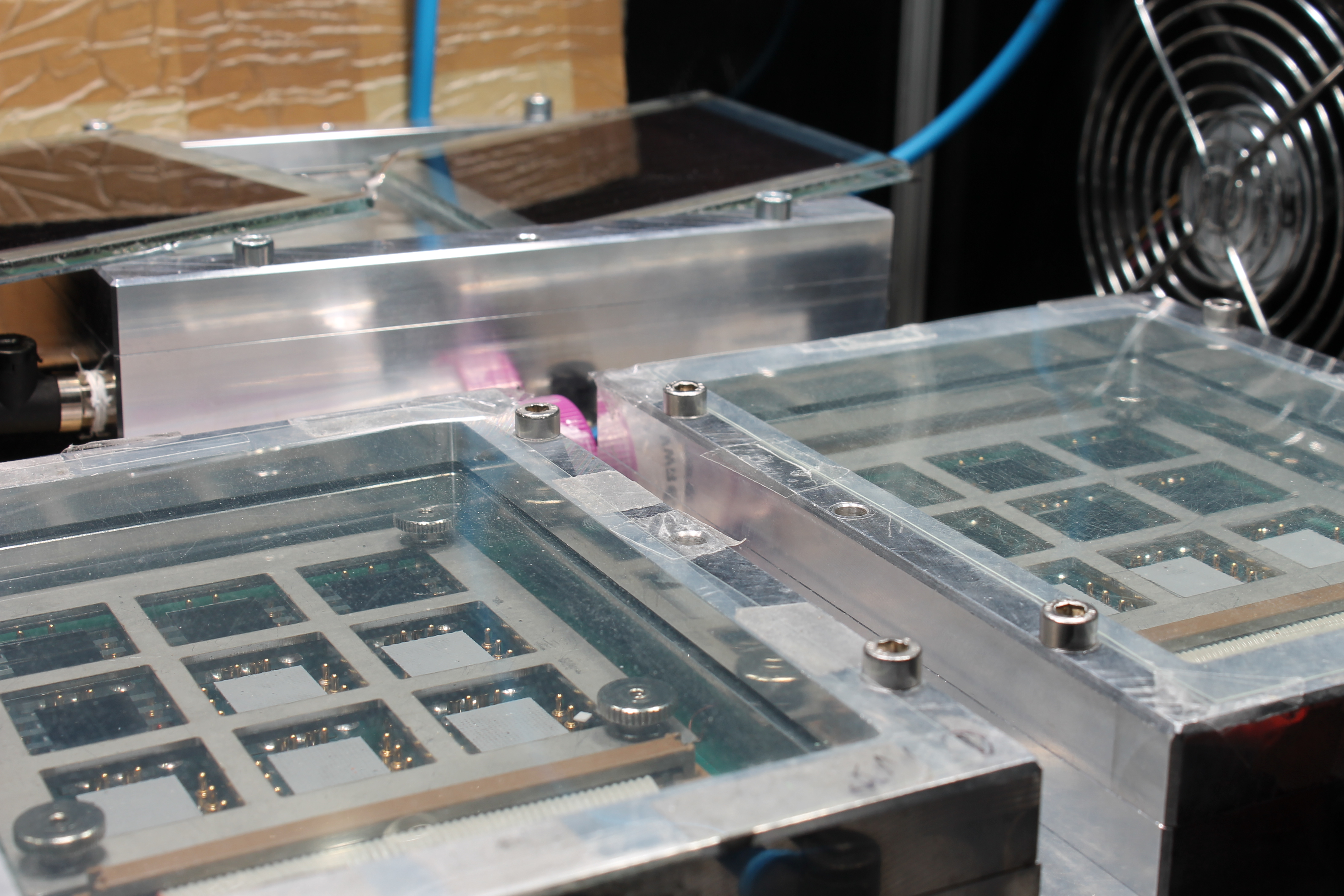

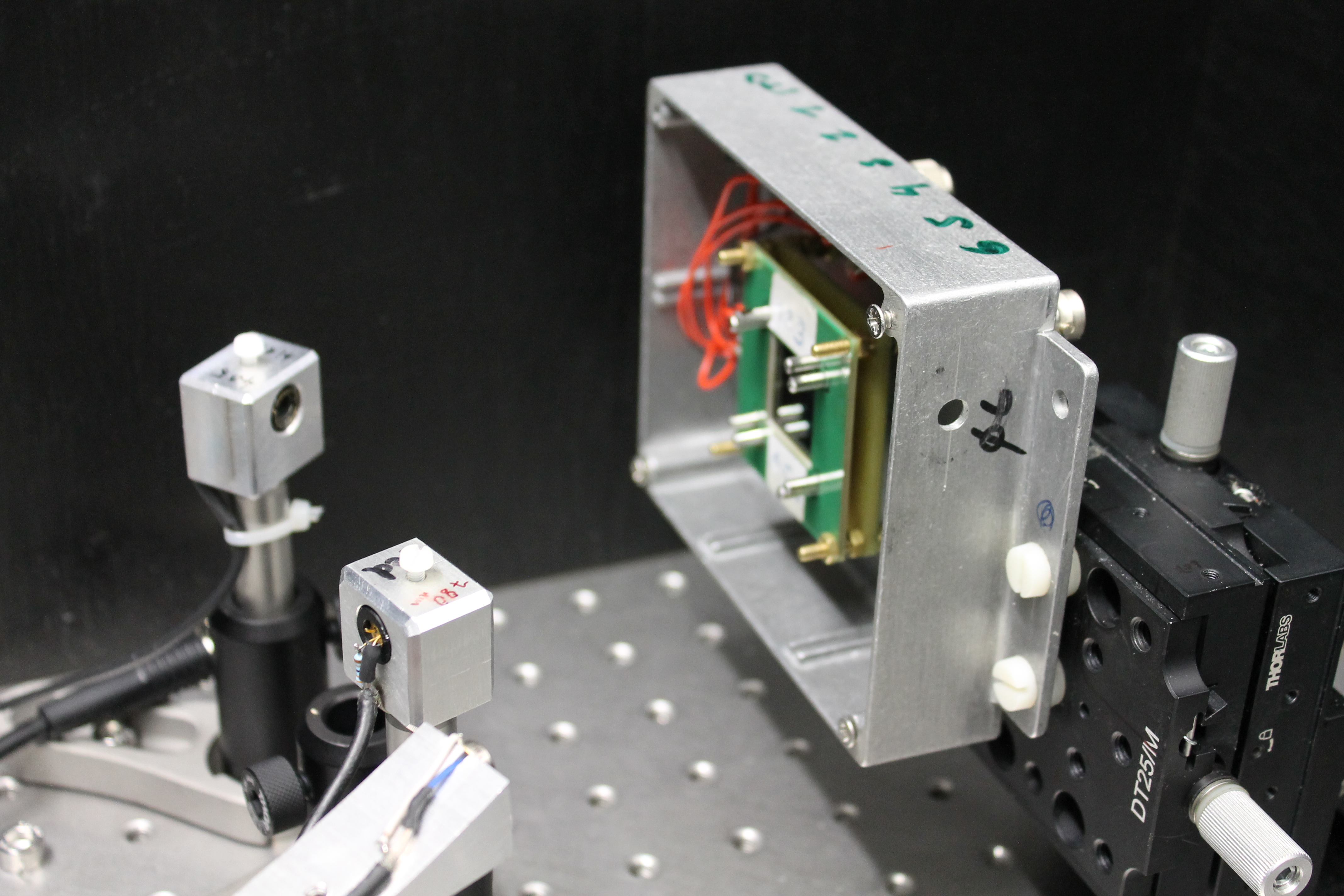

- I-V-testing systems BoTest

- Reflectometer and film thickness analyzer (Filmetrics)

- Transient photocurrent Setup (CELIV)

- FTIR Spektrometer (Bruker, Vertex 70)

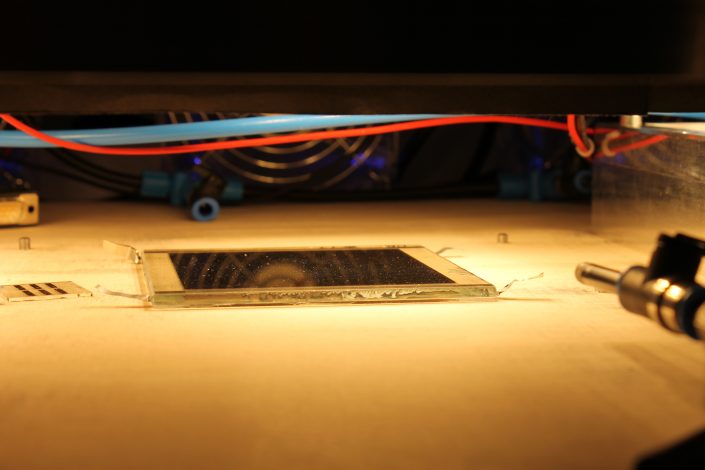

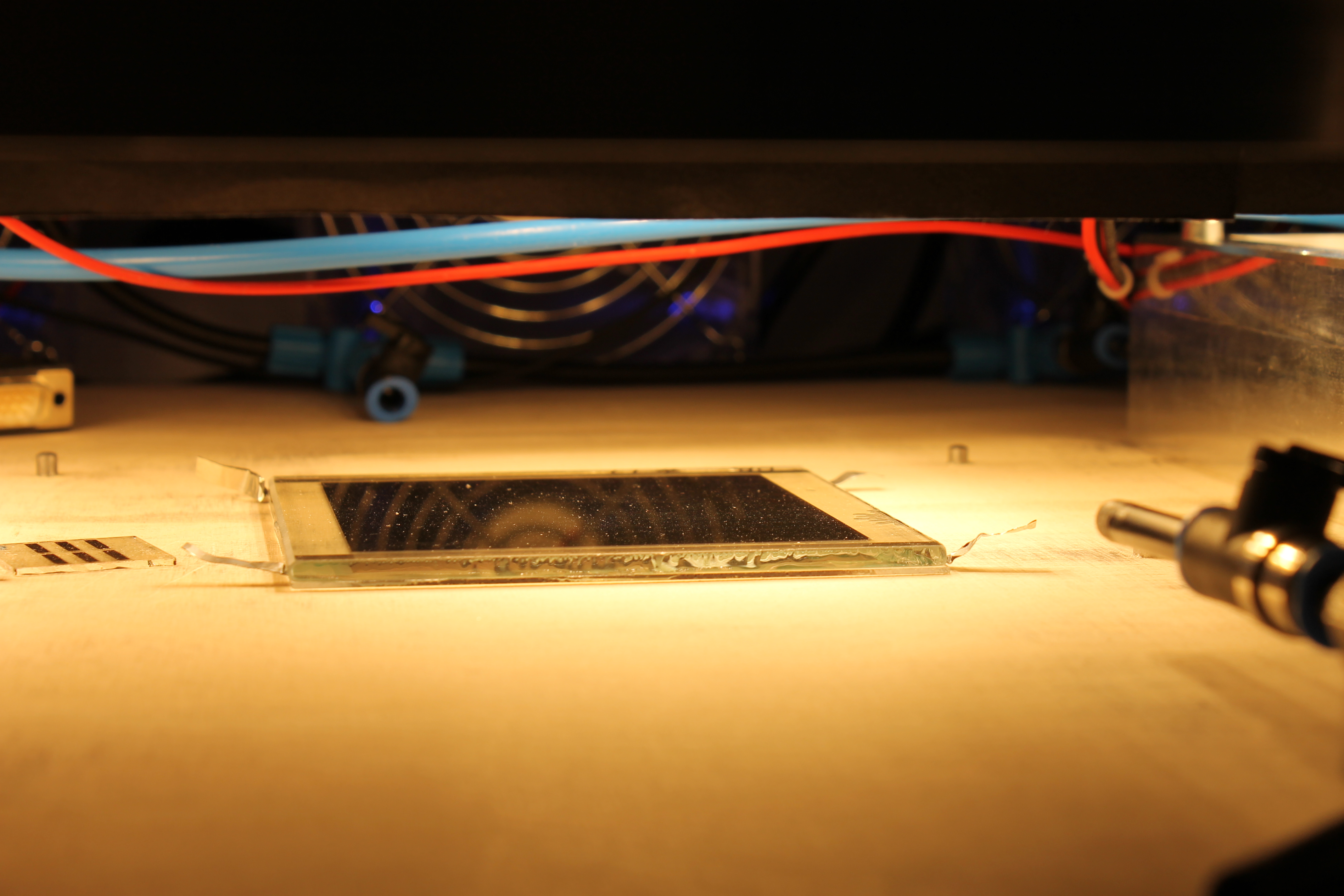

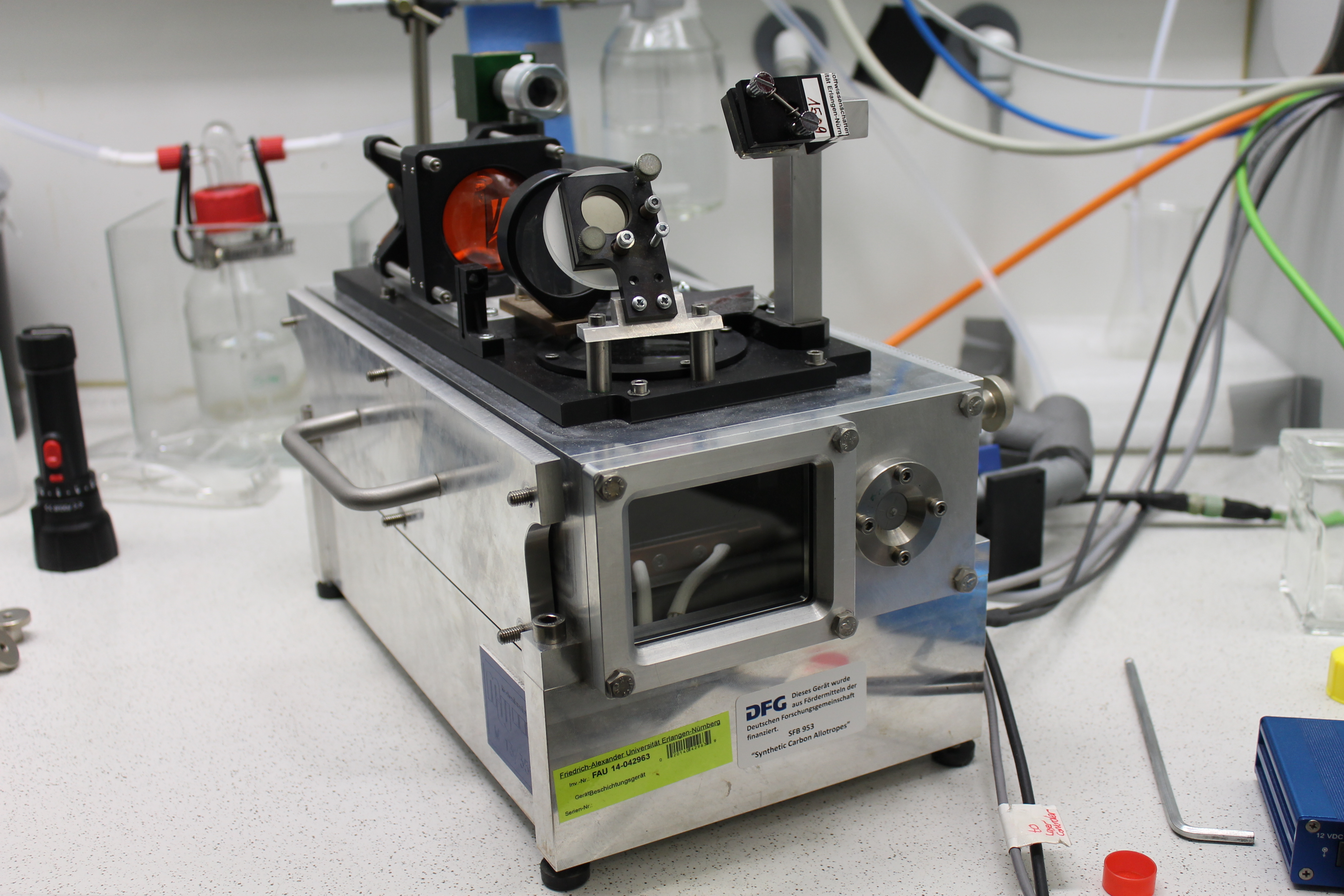

- Optical In Situ Film Drying Analyzer

- Confocal microscope NanoFocus µsurf explorer

- Luminescence microscope with a 532 nm laser (Photon etc.)

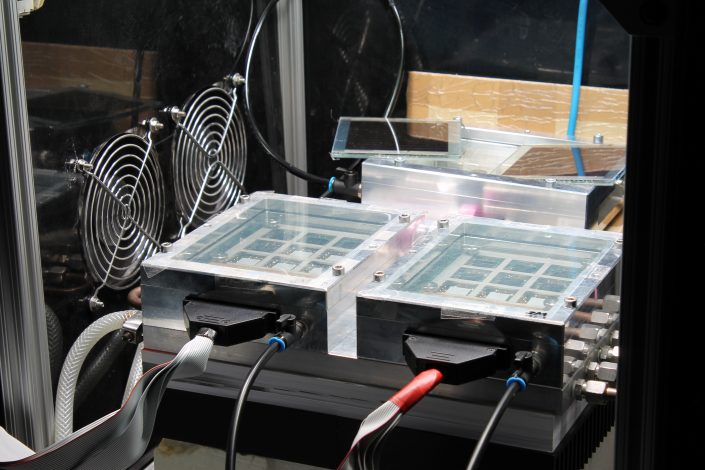

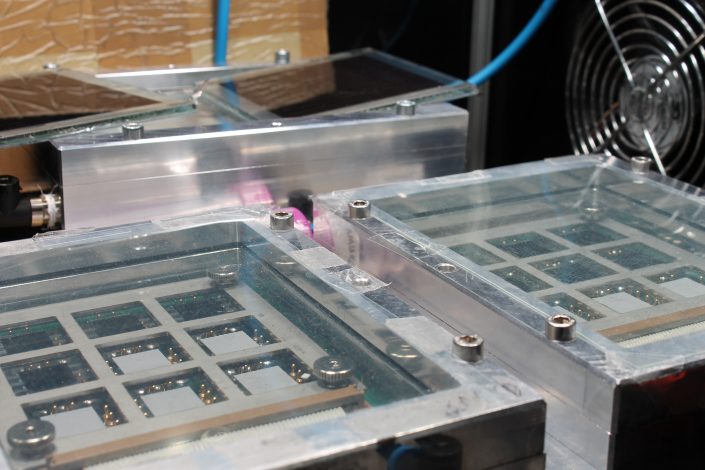

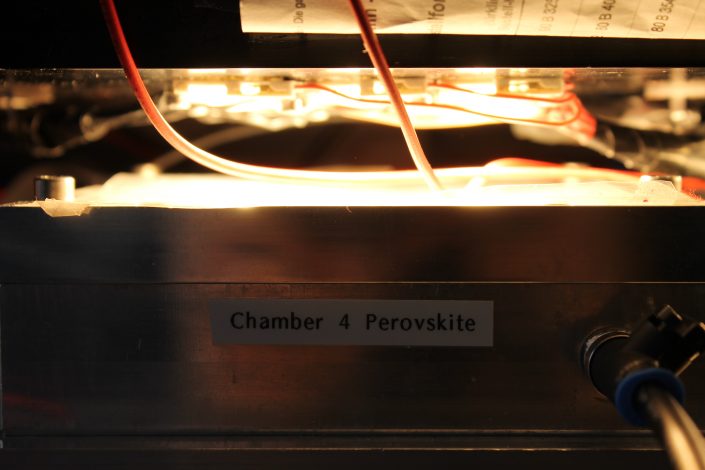

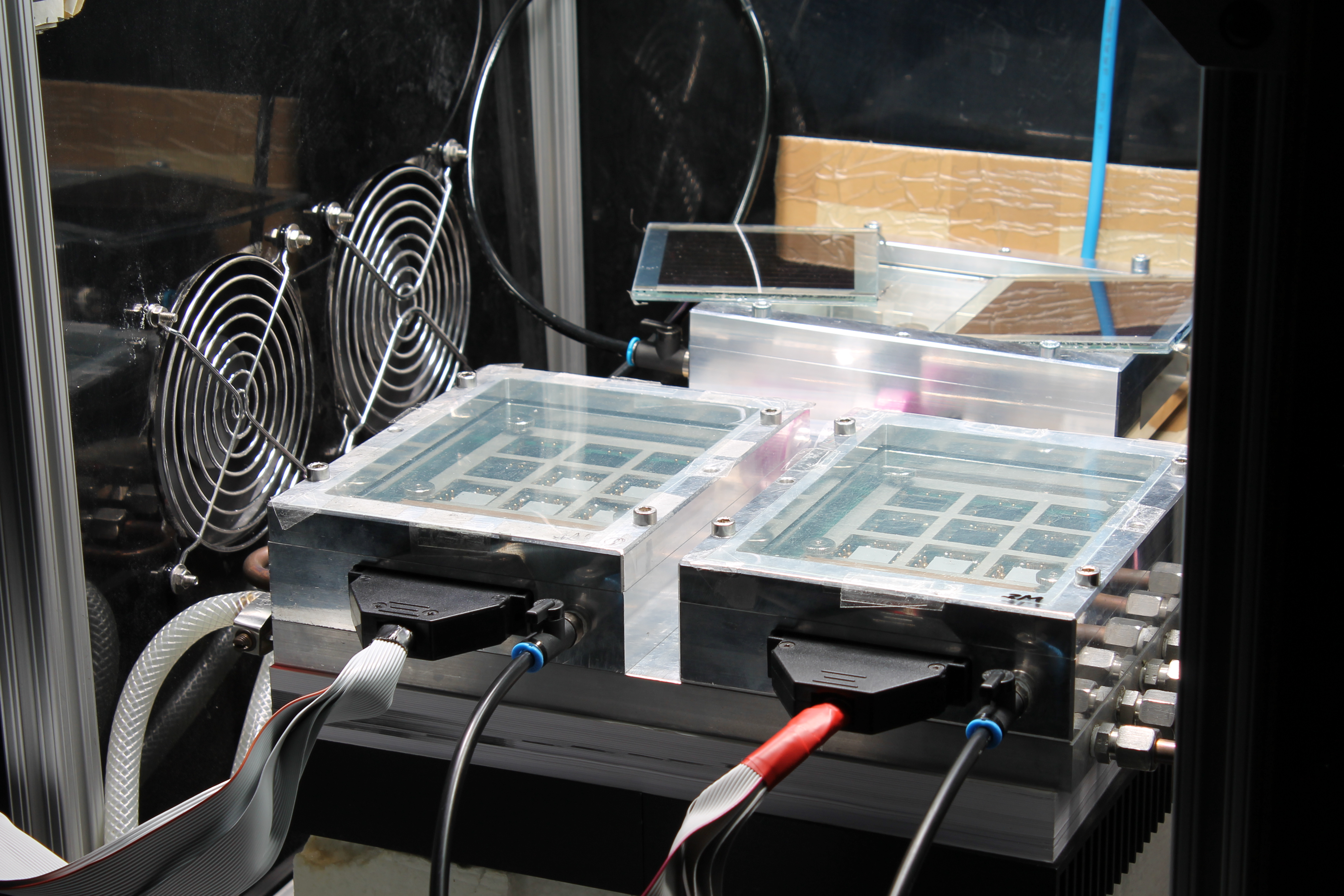

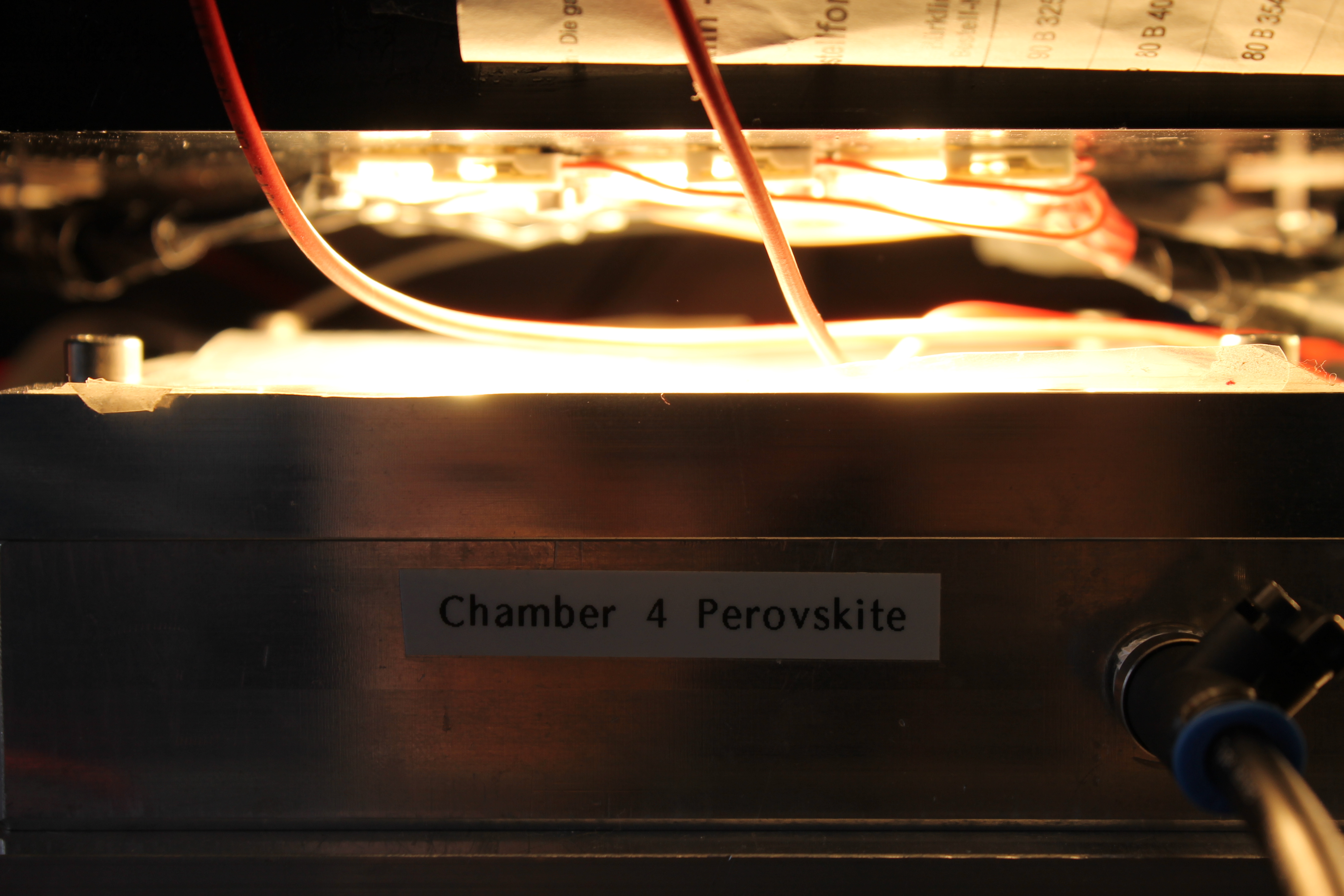

- Accelerated degradation laboratory for solar cells

- Calorimeter Waters DSC Q1000 Auto MDSC

- Oriel Sol1A 6×6 1.0KW Solar Simulator

- Wavelabs LED solar simulator with I-V measurement setup

- KLA Tencor D100 – layer thickness measurement